In some ground conditions pit latrines can be impossible to or dangerous to dig because of collapsing soils. Supported excavations are common throughout the developed world, but these solutions are typically too heavy and require too much specialist machinery to be suitable for humanitarian use. In phase 1 of ESP, Oxfam explored different types of liner, with the view of having a complete liner kit that can be flown in to an emergency response. In ESP Phase 2 Oxfam continued discussions with industrial partners on refine and improve lining solutions. In parallel we engaged with field engineers to better understand needs and constraints they face. The overall conclusion was that there is limited value in developing additional deploy-able equipment because:

i) Industrial partners no not see commercial value in investing their time and resources in producing new/refining existing lining products.

ii) Demand for existing commercial liners is low due to cost and time to import and clear customs.

iii) Because of the above, local improvised solutions are generally preferred.

iv) There are alternative preferable options to digging deep pits in collapsible formations – including urine diversion toilets, tiger worm toilets and container based toilets, which are potentially more cost effective, but often not considered.

In view of the above ESP 2 decided on the following actionpoints.

Firstly to produce a technical brief to capture the range of appropriate solutions for providing sanitation in areas where soils are collapsible:

Second, time and budget resources were allocated to developing a septic tank kit that would provide a first phase solution in all areas of difficult ground, not just collapsible soils.

Phase 1 – work on lining

Two distinct types of soil collapse need to be prevented by the lining and may these may require two different products:

- Crumbly sand at the top of the excavation, meaning that the lining need only support the top 500mm of the excavation.

- Unstable soil for the entire depth, meaning that a full depth solution is required. As pit latrines rely on liquid infiltrating the surrounding soil at least the bottom half of this lining must be permeable.

There are also two distinct types of latrine used in emergency situations:

- Trench Latrines

- Individual Latrines

Each of these may require their own solution, or one product might be developed that is adaptable for all circumstances.

Testing of Trench Linings in the UK

Oxfam tested three different linings in Wales with the assistance of Shelter & Construction Consultants. Using a digger Oxfam tested them to destruction, which resulted in one of the linings being found inadequate and development of it was discontinued (circular pit linings by Newcastle University). The Dunster, Oxford Plastics and Even Product latrine lining kits are awaiting trial in South Sudan (delayed due to logistic and security constraints).Their concepts are presented in the images below.

Dunster

Oxford Plastics

Even Products

Read our report on testing the trench linings in Wales

Design Criteria

| Nature of solution | An all-in-one kit for supporting pit latrine pits in poor soil conditions. |

| Soil types | Pit latrines are only used above the water table. For design purposes, a sandy soil can be assumed. |

| Depth of lining | The lining may either support the top 500mm of the pit, or extend to the full depth, typically 2-3m. Ideally, the solution will be usable in either configuration and adaptable in depth. |

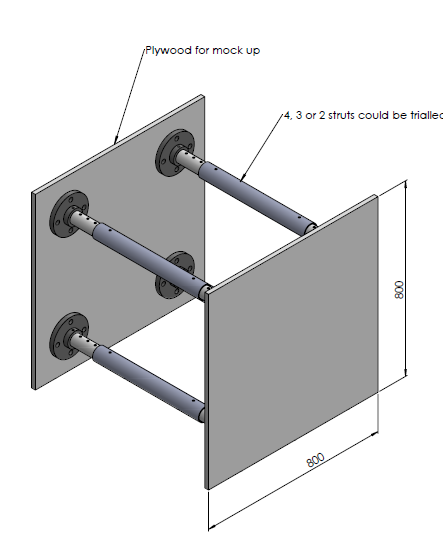

| Strength | For a lightweight lining to be strong enough to line the pit, it is likely to need bracing. These should be lightweight and easy to handle. |

| Durability | Pit latrines are a very aggressive environment. The solution should last for at least 2 years, although ideally longer. It will be single use only and will not be used in more than one pit. |

| Excavation Size and shape | Solutions are needed to accommodate both individual pit latrines and blocks of latrines which may share the same pit. For individual pits a circular excavation is structurally superior, but may be more difficult to pack for shipping. |

| Connection with slab and superstructure | The standard plastic slab that Oxfam currently uses is rectangular measuring 1200 x 800mm. The excavation will allow slabs of this size to be installed on top. |

| Size and Weight | The solution should be as small and light as possible for air freight, and the solution should ideally fit on a EUR-pallet. As a guide, air freight can cost £1-6 per kilogram or £0.20-£1.00 per litre, whichever is greater. On arrival in the country, the solution will need to be man-handleable. |

| Construction method | The solution should be easy to use. Pit latrines are normally dug using spades and pickaxes. |

| Local Materials | The solution should be a complete kit, not requiring any materials to be sourced in country. |

| Cost | There is no fixed price which will be paid for this. As a guide, solutions costing more than £50 / unit are unlikely to be considered. |

The design criteria above outline the envisaged solution, but we are also keen to hear of any radical alternatives.

Tell us your idea

If you have any latrine lining products, ideas or solutions for providing emergency sanitation in difficult ground conditions please get in touch with:

Brian McSorley, Water & Sanitation Advisor at Oxfam

Email: brian.mcsorley@oxfam.org