For difficult ground conditions where it is not feasible to construct pit latrines (rocky, collapsible, flood prone areas) there are a number of alternative options that can be considered. ESP Phase 1 investigated urine diversion dry toilets (UDDTs) and tiger worm toilets. Oxfam’s work on UDDTs in Ethiopia, where we have constructed over 2,500 UDDTs, has led to development of guidelines for UDDT construction that UNHCR has endorsed as a standard solution in difficult ground conditions. More information on tiger worm toilets is available here.

For ESP2, Oxfam has continued its work in urine diversion toilets by focusing on developing urine diversion squatplates which will simplify and speed up the construction of UD toilets, thereby encouraging more agencies to consider urine diversion toilets.

In parallel, we have added a new workstream to develop a septic tank kit which can accommodate the waste of up to 500 users.

Urine Diversion Squatplates

Whilst UDDTs are proven for the transitional period of a humanitarian response as the emphasis shifts from communal to household latrines, their use in the early phase of a response has not been widely tested. This ESP workstream aimed to develop equipment that encourages rapid adoption and scale up of UDDTs at earlier stages of a response by developing:

Product 1) A plastic insert that fits on top of an existing keyhole slab transforming it into a urine diversion toilet* (first phase where pit latrines are not viable).

Product 2) A plastic insert which can be fixed to a concrete slab or timber platform (first phase or transition).

Product 3) A mould to enable high quality concrete slabs and UD inserts to be produced (transition phase to household latrines).

* Consultation with field engineers and industrial partners ruled out developing a self-supporting emergency UD squat plate. This approach was considered much more cost effective.

We decided that there where existing commercially available plastic squat plates (product 2) so rather than duplicate, a desk-based study was done to identify which is most appropriate. This resulted in 10 UD inserts being procured from Sanergy[1] and trialled in Ethiopia.

Following an expression of interest, Oxfam selected Dunster House as an industrial partner to develop the products 1 and 3. During the process, it became apparent that the specification for Product 1, also meets the requirements of product 2, as the need to fit within the dimensions of a keyhole does not significantly compromise the sizing or functionality of either the urine basin or faeces drop hole.

Temporary wooden moulds were fabricated for production of prototypes using vacuum forming. This was considered to be the most cost-efficient manufacturing process for a limited production of prototypes. A total of 31 plastic squat plates and 11 moulds were produced before the moulds became spoiled.

The plastic squat plate is compatible with both the NagMagic emergency keyhole slab (which is the most common emergency squat plate used in humanitarian responses as well as the Dunster House squat plate (that the Oxfam Supply Centre currently uses). A bracketing system which fixes to existing threaded bolt holes present in both squat plates, secures the UD insert in position with plastic spaces used to accommodate the different thicknesses of each slab. A rubber gasket ensures a tight seal between the insert and the underlying slab.

The squat plate was also compatible with a number of other slabs. Key compatibility considerations are the same size of keyhole and footrest configuration. It the keyhole is smaller or the gap between footrests narrower, then the insert is unlikely to fit. Whether existing bolt holes are not present within the self-supporting keyhole slab, the brackets are not required and would be replaced by drilling hole through the slab and securing with a bolt and nut from above and below. This same method would be used for a timber or concrete floor.

A mould for local production of UD squatplates

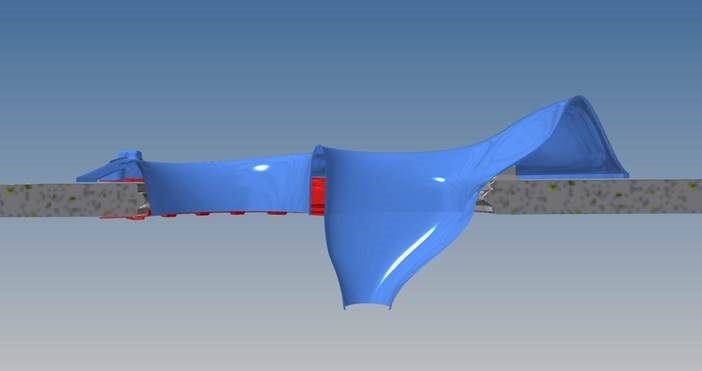

Challenges were faced in production of the UD mould (Product 3) due to limitations of the manufacturing process. Vacuum forming stretches a piece of plastic onto a mould. The greater the depth of the mould the further the plastic needs to stretch and consequently the thinner and weaker it becomes. The urine basin was designed with a steep front lip to fully contain urine and prevent overflow (see below CAD drawing). This had to be reduced to retain the strength of the mould.

Deployable Septic tank Kit for First Phase Emergency Response

In rapid on-set emergencies where large numbers of people are displaced agencies first set up communal latrines. Where there is space and the ground allows, trench latrines are still the cheapest and quickest option. However, with increasing number of displacements happening in situations where it is impossible to dig trench latrines due to rocky or water-logged ground, lack of permission from landowners and lack of space or lack of access for desludging it is becoming more frequent for raised latrines to be used. After the Haiti earthquake, Oxfam and other agencies had to build huge numbers of raised latrines in the urban areas, each cubicle had 50+ users, the slabs were direct drop and people took in containers of water for anal cleansing. Each cubicle had around 1 m3 containment beneath it and had to be desludged once every 4 days. The cost of a desludging tanker at that time was around US$150 for 4m3 resulting in substantial ongoing operating and servicing costs of toilets. Lowering the desludging frequency to once a month would have saved US$ 750 per month for each block of four latrines

Past initiatives to deploy compact treatment units have been vastly expensive, and a previous attempt to make a flat packed septic tank failed as it was too fragile. Urine diversion and tiger worm toilets are suitable in difficult ground conditions but are not suitable or appropriate at scale for 1st phase communal toilets where a rapid set up is required and the users are between 50 and 100 people per toilet.

Oxfam identified Bremen Overseas Research and Development Association (BORDA), a German based NGO specialising in decentralised sanitation solutions, as the most appropriate technically qualified partner to co-create a modified prefabricated Septic Tank Kit system for the rapid on-site application in emergency camps. In November 2017 a 1-day scoping workshop was held in Germany which developed the following requirements for the product:

- Safely collect, store, treat and dispose of faecal wastewater from shared water-born toilets used by 300-500 people per day. It is envisaged that toilets could be direct drop or pour flush, with several cubicles (serving 50-100 people) connected to each septic tank.

- Ensure the treatment of the faecal wastewater to the quality required for disposal via ground infiltration, vegetative leach field or sewer drain.

- Optimise sludge storage to reduce the frequency of desludging.

- Be designed in a kit system in a way that can transported by airfreight, be easily assembled within one day, and be operated for a period of up to 12 months.

- Consist of durable pre-fabricated elements that are available on the international market with a potential to be manufactured locally.

- The system should be suitable in all climate regions and for different sanitation cultures (washers and wipers) without requiring modifications and adaptations

- Requires an excavation depth of no more than 1.2 metres.

- To prevent legal conflicts the system should only consist of non-permanent structures, which can be easily removed when they are no longer required.

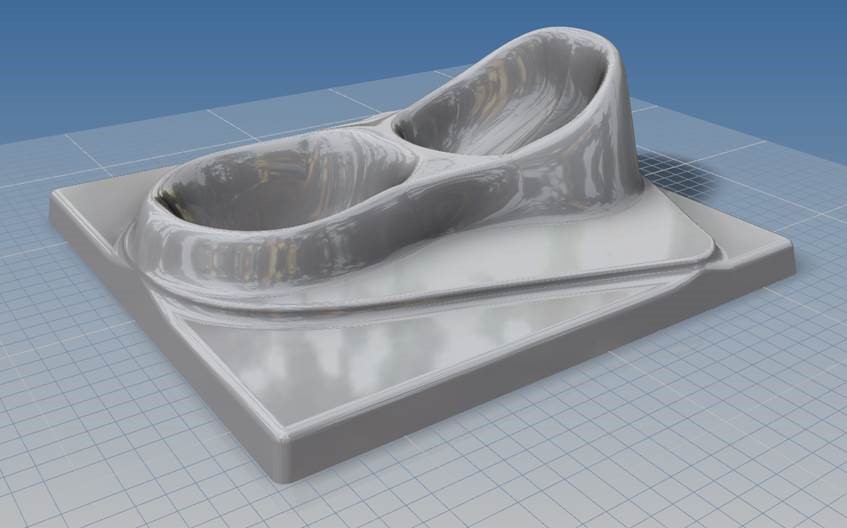

A feasibility study concluded that a bladder based construction from the most appropriate material

To date there have been 3 stages of trials:

GENAP factory – Netherlands. This initial field trial was undertaken jointly between Oxfam, BORDA and GENAP in Netherlands in June 2018. The septic tank bladder was laid out and filled with water to provide an initial indication of functionality. This identified the need to modify the desludging pipe system and highlighted a possible weakness of gas tight zips as a means of accessing inside the septic tank. More details are attached in this report.

Bremen Sewage Treatment Works – Germany. Following some minor modifications, a more extensive, 3-week duration pre-field deployment was undertaken by BORDA at a sewage treatment works in Bremen where the performance of the bladder was tested with sewage. On the basis of this successful trial, two complete septic tank kits where manufactured for deployment in an ongoing emergency. See attached time lapse for more details.

Oxfam Supply Centre, UK. As part of a technical learning forum for Oxfam’s global surge team of engineers, BORDA was invited to UK and the complete septic tank kit was unpacked and partially set up within the Oxfam warehouse. Feedback was generally very positive but a number of observations and suggestions have been made on further improvements and how to optimise the kit as and when it is turned into a commercial product.

Next Steps

Pre-field trial in Germany has verified the integrity of the kit as well as the technical performance. This workstream was only initiated in phase 2 of the Emergency Sanitation Project, it has been difficult to complete all stages of product development from concept, feasibility, manufacture, pre-field testing, field testing then looping back to make any necessary modifications for a final product. Ultimately confirmation that it is fit for purpose can only be determined as a result of a live deployment and active field trial.

BORDA has confirmed its interest to commercialise the septic tank kit. This requires further work with an industrial partner. The price point of the unit is still an area Oxfam and BORDA are working on to bring it to a price that is as competitive as possible. Cost effectiveness needs to be judged by consideration of both capital and recurrent costs (which humanitarian responders and donors frequently overlook.

Endnotes:

[1] Sanergy is a Kenya based social enterprise which operates a toilet franchising and servicing business covering over 3,000 UD toilets. They undertook significant research prior to designing their own urine diversion squatting plate. Oxfam decided to trial Sanergy squat plates based on the well tested and proven functionality of these toilets in Kenya.

Tell us your idea

If you have any products, ideas or comments related to the above content please get in touch with:

Brian McSorley, Water & Sanitation Advisor at Oxfam

Email: brian.mcsorley@oxfam.org