(new!) Sludge Reservoirs

(new!) Sludge Screen

Development of desludging equipment for emergency response

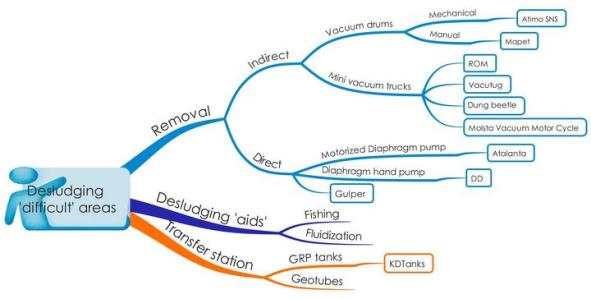

Options for desludging – Difficult Areas

Objectives:

- Improved ability of field teams to rapidly mount desludging activities.

- Development and testing of single desludging kit using existing materials, including desludging pump, transport storage, and all accessories.

Activities:

Activities were executed (see mindmap below):

- § Review desludging difficult areas;

- § Design and produce prototypes;

- § Testing in the field.

Review desludging difficult areas.

We studied what is available on the market and visited producers such as the producer of the Atimo drum solution in Italy.

Design and produce prototypes.

Three desludging units and a transfer station were chosen for further development and testing.

- WASTE opted for the ROM2 vehicle, a vacuum-operated machine with 800 litres holding tank, and had it tailored for emergency situations and ‘difficult’ sludge: in-built fluidizer, larger (3” instead of 2” hose), etc.

ROM2

- The Netherlands Red Cross (NLRC) and the Malawian Red Cross partnered in this part of the project and donated some of the equipment so that the Vacutug and the fluidizer could be included in the tests. NLRC wanted to have a fair comparison with the current standard at the market, the Vacutug. As this unit does not have a fluidizer, an off-the-shelf fluidizer was selected.

Vacutug Mk2

- IFRC chose a flat pack desludging kit with 3 m3 tank, membrane pump, and valve and hose manifold which allows the unit to be filled and emptied without disconnecting hoses.

Top to bottom: Flat pack desludging kit, Membrane pump, Kit mounted on truck

- For the transfer station a 13-m3 bladder was purchased.

The setup of the field trials included:

- § Fluidization;

- § Fishing of rubbish;

- § Emptying of pit;

- § Temporary storage in transfer station;

- § Transport to treatment facility.

Testing in the field.

The tests in the field, Malawi, began in November 2013 and continued up to the end of June 2014.

From the testing in the field of the ROM2 it became apparent that it is easier to have a separate fluidizing kit. Hence, the fluidizer attached to the suction hose of the ROM2 was detached. It was also clear that at least 30 m’ of 3” suction hose is needed to operate successfully in order to access toilets. Despite all the ‘fishing’ activities, still debris is entering the ROM 800 litre vacuum tank; hence a separate manhole is to be put in place to facilitate maintenance. Otherwise the ROM2 functions perfectly as long as the fluidizer is used and rubbish is fished out. It has been tested on over 350 toilets, removing over 435 m3 of difficult sludge including emptying of toilets abandoned as full for several years. It is robust and reliable, and requires maintenance after 250 toilets. It has also been mounted on a trailer to be towed by a 1-ton truck in order to further enhance accessibility. It is recommended that the item be added to the catalogue of relief agencies once the changes recommended by the project.

A separate high-pressure device, Karcher, was purchased and tested with different nozzles to find out what set-up is best to fluidize sludge and what would be the best pressure. It was concluded that the pointed nozzle works best. Using the pressure washer we had initially planned to fluidise 25 pits with each of the Vacutug and the diaphragm sludge pump. This target was not possible for two reasons:

- The diaphragm pump proved suitable for relatively ‘clean’ septic tank sludge and unsuitable for use in pits with significant amounts of rubbish as this interferes with the sealing of the port valves. While the pump is perfectly adequate for septic tanks with little or no rubbish, its use in pit toilets was abandoned;

- The team experienced many problems with the reliability of the Vacutug – broken drive systems, starting system, etc. Although the Vacutug is designed to be self-propelled, due to its lack of manoeuvrability it was not able to access may toilets even though we used a 30m suction pipe. Part of the limitation was that once the tank was full, the Vacutug was difficult to move to the disposal site. Therefore the sludge from the Vacutug had to be transferred to a storage tank, and then the ROM was used to empty the tank and transfer to a 13m3 bladder which was on site about 100 m away. However, the lower cost of the Vacutug in comparison the ROM should be considered in equipment selection.

It is unlikely that one desludging unit would be suitable for all contexts. More likely is that different equipment would be used in a ‘hub and spoke’ configuration, with smaller units collecting sludge from less passible areas and bringing it to a collection point for transport o the final disposal site. This collection point needs to be able to store waste safely and with minimal nuisance.

The use of the bladder is successful as it reduces transport movements – in conjunction with the ROM 800 the team was able to empty 8 pits in a working day. It was slightly damaged and a repair kit on-site is needed. However as the bladder has an inner and an outer bag, repairs are not easy. The bladder is recommended in cases where it is not meant to be relocated frequently as it is easily damaged during transport. In order to avoid environmental accidents in the case of punctures, the bladder should be positioned in a depression at least 30cm deep. Even after leaving sludge in a bladder for 4 weeks it was still possible to empty the bladder. The bladder is also effective in containing unpleasant smells.

Emptying bladder/ Transfer station

After extensive modifications we found that it is possible to empty difficult accessible pit latrines with thick sludge in an effective and efficient way with a mobile pit-emptying machine. These machines are capable of handling most sludge in lined and unlined pit latrines and in septic tanks and able to access a high percentage of toilets. The key components of such a mobile desludging unit” should include:

- § A fluidizer that can spray high-pressure water at around 60-100 bar;

- § Fishing equipment such a hooks to remove rubbish;

- § A vacuum pump capable of creating a vacuum of 0.5 bar, with a capacity of at least 2000 litres per minute. Membrane pumps are effective with septic tanks. Other pumps may also be effective in desludging a variety of pits;

- § Three-inch flexible suction and outlet hoses in order to avoid frequent blockages by un-fished rubbish;

- § A holding tank of 1000 litres to store and transport sludge. The inside of the tank should be easily accessible in case the discharge port becomes blocked;

- § The unit should be mounted on a small truck or trailer and the lengths of the suction pipe and fluidizing hose should be increased to 30 metres to increase accessibility;

- § Improvements in the logistics of operating the unit, including access to localized disposal (or a transfer station), make it possible to desludge up to eight pits in one working day.

The final full report of the desludging trials is available at www.emergencysanitationproject.wordpress.com and http://www.waste.nl/en/product/testing-desludging-units-for-emptying-pit-latrines-and-septic-tanks

Dissemination of awareness of equipment developed is an important part of this project and the work was presented at the Global WASH Forum in April 2014 in Oslo. The web based emergency items catalogue of the IFRC and ICRC (http://procurement.ifrc.org/catalogue/) which is publically accessible will also be updated to include this item, and a one pager on this equipment with key technical information, costs, and contact information will be included in the information published on the SuSanA website. Two reports have been produced to disseminate the findings: one short summary for the general public and one elaborate report with more details. The reports have been promoted intensively through mailings, SuSanA website and the results will be presented in the WEDC conference July 2015.

Further research needs

This work stream of the ESP is significantly developed, and the equipment has been received positively by practitioners aware of the equipment. MSF Amsterdam is considering purchasing equipment for rapid deployment. A real emergency is the next further trial needed for this equipment. In the meantime, ignited by the ESP efforts, ROM equipment is being purchased by several development projects in Malawi (sponsored by EU and BMGF).

However, it has been observed that there are a large number of pumps which may be suitable to this application and other pumps should be tested for their usefulness in desludging. One such pump is the Tesla Pump which is a bladeless centripetal flow turbine particularly suitable to desludging but which needs further development and trialing in this context before it can be used.

Desludging report:

Desludging in ‘difficult’ areas

Elaborate field tests identify suitable equipment for emptying full latrines in emergencies

Manual emptying is an unhygienic job and available equipment usually fails to deal with thick sludge, often mixed with solid waste, or might be expensive and not able to reach near the pit latrine. In the framework of the Emergency Sanitation Project WASTE and NL Red Cross have tested different equipment in Malawi and based on those tests and current knowledge came up with clear suggestions for the ‘ideal’ set that comprises of fluidisation, fishing of rubbish and emptying. The results are summarised in a short report and an elaborate report. At the WEDC Conference in July 2015, Jan Spit of WASTE will present a paper on the findings.