Sometimes it’s not possible to dig pit latrines and instead it’s necessary to build upwards. This could be because of a high water table, frequent flooding, rocky ground or where digging into the ground is not permitted. There are a multitude of ways of raising a latrine: whether by creating an earth mound, a wooden frame or a concrete block structure. What we are looking for, however, is a kit solution that can be quickly and easily shipped and set up in a variety of different situations. Two different circumstances in which the raised latrine might be used are envisaged: a solution where excreta and urine are held together (a ’shit soup’ solution) and a urine diversion solution.

The All-in Solution

Excreta and urine are kept together and empty into one container. This could either involve the excreta dropping straight into the container or the use of a pour flush system. It is envisaged that this container might become full quickly and therefore require frequent emptying, or swapping, so this solution is likely to be more suitable. As a guide, a latrine that served fifty people and was emptied on a weekly basis, with each person producing 2? per person per day, the tank would need to be around 1m3.

Design Criteria

| Nature of solution | A versatile kit for raising a latrine, consisting of the structure to raise the latrine and a container for collecting the excreta which allows emptying. |

| Configuration | The solution should be a block of latrines, an individual latrine or, ideally, be configurable to both situations. |

| Size and shape | Oxfam’s existing pit latrine slab is 1200 x 800mm. The solution should preferably fit on the existing slab, although alternative solutions may be considered. The solution can also make use of the latrine superstructure which is also being developed as part of this project. |

| Disabled Users | The solution may cater for disabled users, although this is not essential as alternative solutions could be found. |

| Durability | Minimum two years. |

| Weight | On arrival in the country, the solution will need to be man-handleable. |

| Packaging | The solution should pack small for ease of shipping. Ideally, the solution will fit on an EUR-pallet. |

| Construction method | The solution should be quick and easy to use, requiring little or no skill. |

| Local Materials | The solution should be a complete kit, not requiring any materials to be sourced in country. |

Objective

Develop, test and have ready for production at least two emergency raised latrine models. They will be suitable for air freight, affordable, durable and be easy to install.

Activities

Design a Bog Day

Design a Bog day was organised as a networking and design event. It gathered together a mixed group of NGO workers, representatives from suppliers, academics and product designers to come up with solutions for the latrine kits and handwashing devices. Attendees from beyond the field of sanitation were sought, with adverts put out in relevant press to search for product designers and potential manufacturers. This brought together people who would approach things differently and meant networks could be built between people who might not normally meet.

Outcomes are documented in an article which was published in Waterlines, and a written and audio article on the IRIN website:

http://www.irinnews.org/report/98787/new-look-emergency-sanitation

Grants to support the development of kits.

After a selection process grants of £5,000-10,000 were given to Dunster House, Compact Shelters, Flexxolutions, Coventry University and Econoplas to develop their kit designs.

Test of Evenwaste and nCircle latrines in Bundibugyo, Uganda

Three Evenwaste raised latrines and fourteen nCircle superstructures were sent to the refugee transit centre in Bundibugyo, Uganda, where Oxfam has been responding to an influx of refugees from the Democratic Republic of Congo. This resulted in a lot of learnings which have been applied to the development of the kits.

Global WASH Cluster Meeting

http://washcluster.net/wp-content/uploads/sites/5/2014/06/19th-Global-WASH-Cluster-Meeting-Minutes-Final-Draft-Oslo-2nd-and-3rd-of-April-2014.doc

Twelve different kit models were taken to the Global WASH Cluster meeting in Oslo. Feedback was sought from the attendees and they were instrumental in narrowing down the products to continue to work with only a handful.

Humanitarian Learning Forum

Oxfam holds an annual event, the Humanitarian Learning Forum, where many field staff gather together to exchange learnings. We brought in all of the kit suppliers to present their products, gather feedback and advertise their existence.

Testing Dunster House Raised Latrines in South Sudan & Central African Republic

Raised latrines from the suppliers Dunster House and Flexxolutions were used by the Oxfam cholera response in Juba, and the Oxfam IDP response in Bangui. Feedback from this trial has resulted in significant design improvements ranging from changing the locks to make them less easy to steal, changing the way the steps attach, and the step height, making the instructions for assembly clearer (pictorial) and strengthening the slab floor span over the raised tanks.

Tendering rapid latrine superstructure, durable latrines superstructure and raised latrine

Oxfam are able to present two options for the superstructure; one which is a rapid superstructure, which can be assembled in a matter of minutes and replaces the likes of plastic sheeting and wooden pole and a second one which is a more durable latrine.

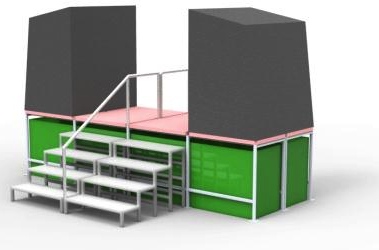

The following images present the concepts being developed both by Dunster, Even Products, Aircell and Flexxolutions for the raised latrine concept, and the durable superstructure.

Aircell

Dunster House

Even Products

Flexxolutions

A Public Health Engineering Advisor, and the Logistics Equipment Quality Officer have together visited all the above suppliers and assembled their rapid, durable superstrucutres and raised latrines to gauge how intuitive they are to assemble, and appraise which of the specifications one likes and dislikes. Next steps are now, a tender has been launched by the logistics team with a closing date of the end of June 2015, to bring these 3 concepts to a conclusion based on their price, weight, volume, specifications, and the appropriateness in solving the original problem statement. Oxfam intend to include these successful items in the Equipment Supply Catalogue, which can be ordered both by Oxfam field staff and external agencies through our recently launched Humanitarian Procurement Centre. In the meantime, Flexxolutions, supported by WASTE, has been able penetrate the market. To date 116 toilets have been sold to MSF to be used in Iraq. A second order consisting of 82 toilets is going to be sent to Nigeria via MSF France.

Tell us your idea

If you have any products, ideas or would like to become involved in the latrine lining project please get in touch with:

Angus McBride, Emergency Sanitation Researcher at Oxfam

Email: amcbride@oxfam.org.uk

Phone: +44 (0) 1865 473814

Netherlands Minister of development cooperation is inspecting the raised latrines

One of the outcomes of the ESP is the Raised Toilet by Flexxolutions.

During the pre-event of the Humanitarian World Summit in Den Haag, the new sanitation innovations of WASTE, the Red Cross, ROM and Flexxolutions were displayed and visited by Lilianne Ploumen, the Dutch Minister for Foreign Trade and Development Cooperation, who expressed her support for the project.